When a tyre pressure control system makes sense

Tyre pressure regulating systems (RDA) save money where machines often switch between field and road with varying payloads. The tyre pressure should be as low as possible to protect the soil when working in the field. This increases the contact area, resulting in less slippage and fuel savings. In addition, a larger footprint reduces soil compaction and thus improves harvesting.

On the road, on the other hand, the tyre pressure should be as high as possible in order to save fuel with lower rolling resistance and to protect the tyre. Even though an RDA is not exactly cheap to buy, the investment is worthwhile, as Prof. Dr Ludwig Volk has shown for the "DLG-Merkblatt Traktion". Tyres that are run in the correct pressure range last around 1,000 operating hours longer. In addition, the tractor's tractive power and fuel consumption improve by up to 10 percent, as the study by Prof. Dr. Volk proves.

Suppliers and features of tyre pressure regulators

The market for tyre pressure control systems is quite clear on the supplier side. Notable suppliers are PTG Reifendruckregelsystem GmbH from Neuss, the company Steuerungstechnik StG from Hilter a. TW and the tractor manufacturers Fendt and Claas, which offer their own systems. The different systems differ noticeably in terms of price and performance. In addition to virtually maintenance-free installations, there are makes with additional compressors, such as are useful for particularly large and voluminous tyres. These compressors must be freshly greased at regular intervals, which increases the maintenance effort. Another performance feature of tyre pressure control systems is the speed at which an adjustment of the air pressure can be made. Some allow pressure adjustment only when the vehicle is stationary, others at speeds from 10 up to even 60 km/h - of course always depending on attached or towed implements and machines.

Install prepared rims

A normal wheel is not directly suitable for the installation or retrofitting of a tyre pressure regulation system. If changes are made later, for example by the workshop, the warranty may be invalidated. Therefore: for tractors and vehicles that have a certain range of use, keep this in mind beforehand.

The prepared rims are delivered with a sealing plug so that the customer can decide to have a tyre pressure regulation system retrofitted at any time. The trade has the right adapters for every standard bore.

a. Timing for the tyre pressure change

Only after reaching the field should the pressure be lowered and raised again before leaving the field. Otherwise, the tyre may be damaged. Even if this only becomes noticeable later, the service life of the tyre suffers considerably. A carelessly adjusted air pressure will also damage the tyre in the long run.

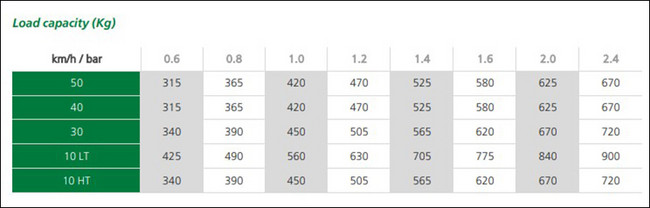

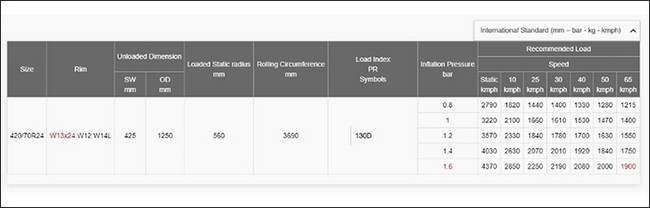

b. Air pressure tables are the be-all and end-all

If you know the weight of your machine and how fast you are allowed to go on which surface, you can easily read off the ideal tyre pressure for the tread from an air pressure table. Such fine-tuning is sometimes disregarded in operational practice.

Measuring machines

A tractor only achieves a big plus in performance when the tyre pressure is precisely matched to the intended use, the respective load and the speed. To do this, workshops or vehicle operators must first weigh the machine with and without the attachment. Users can then read up on the ideal pressure range in a so-called air pressure table. The individual table for each tyre can be found either at the tyre manufacturer's or at the tyre shop.

IF and VF tyres have an advantage with air pressure control

If possible, IF and VF tyres should also always be installed with a tyre pressure regulation system. They can be driven with a significantly lower tyre pressure at the same load capacity. For the use of an RDA, this means: because the air pressure only has to be increased or decreased by a few bar, the necessary air pressure adjustment is lower. This saves a lot more time and increases the driver's willingness to use the system.

One more selling point to finish

Since 23 June 2021, after a break of around six months, farmers can again apply for a grant from the federal energy efficiency programme for the purchase of automatic tyre pressure control systems. The subsidy rate is 30 percent. Machinery pools and contractors are excluded. In contrast to the previously applicable rules, the eligibility conditions have been tightened. Only RDAs that cover all axles of the vehicle are now eligible; previously, retrofitting the rear axle was sufficient.

When a tyre pressure control system makes sense

Tyre pressure regulating systems (RDA) save money where machines often switch between field and road with varying payloads. The tyre pressure should be as low as possible to protect the soil when working in the field. This increases the contact area, resulting in less slippage and fuel savings. In addition, a larger footprint reduces soil compaction and thus improves harvesting.

On the road, on the other hand, the tyre pressure should be as high as possible in order to save fuel with lower rolling resistance and to protect the tyre. Even though an RDA is not exactly cheap to buy, the investment is worthwhile, as Prof. Dr Ludwig Volk has shown for the "DLG-Merkblatt Traktion". Tyres that are run in the correct pressure range last around 1,000 operating hours longer. In addition, the tractor's tractive power and fuel consumption improve by up to 10 percent, as the study by Prof. Dr. Volk proves.

Suppliers and features of tyre pressure regulators

The market for tyre pressure control systems is quite clear on the supplier side. Notable suppliers are PTG Reifendruckregelsystem GmbH from Neuss, the company Steuerungstechnik StG from Hilter a. TW and the tractor manufacturers Fendt and Claas, which offer their own systems. The different systems differ noticeably in terms of price and performance. In addition to virtually maintenance-free installations, there are makes with additional compressors, such as are useful for particularly large and voluminous tyres. These compressors must be freshly greased at regular intervals, which increases the maintenance effort. Another performance feature of tyre pressure control systems is the speed at which an adjustment of the air pressure can be made. Some allow pressure adjustment only when the vehicle is stationary, others at speeds from 10 up to even 60 km/h - of course always depending on attached or towed implements and machines.

Install prepared rims

A normal wheel is not directly suitable for the installation or retrofitting of a tyre pressure regulation system. If changes are made later, for example by the workshop, the warranty may be invalidated. Therefore: for tractors and vehicles that have a certain range of use, keep this in mind beforehand.

The prepared rims are delivered with a sealing plug so that the customer can decide to have a tyre pressure regulation system retrofitted at any time. The trade has the right adapters for every standard bore.

a. Timing for the tyre pressure change

Only after reaching the field should the pressure be lowered and raised again before leaving the field. Otherwise, the tyre may be damaged. Even if this only becomes noticeable later, the service life of the tyre suffers considerably. A carelessly adjusted air pressure will also damage the tyre in the long run.

b. Air pressure tables are the be-all and end-all

If you know the weight of your machine and how fast you are allowed to go on which surface, you can easily read off the ideal tyre pressure for the tread from an air pressure table. Such fine-tuning is sometimes disregarded in operational practice.

Measuring machines

A tractor only achieves a big plus in performance when the tyre pressure is precisely matched to the intended use, the respective load and the speed. To do this, workshops or vehicle operators must first weigh the machine with and without the attachment. Users can then read up on the ideal pressure range in a so-called air pressure table. The individual table for each tyre can be found either at the tyre manufacturer's or at the tyre shop.

IF and VF tyres have an advantage with air pressure control

If possible, IF and VF tyres should also always be installed with a tyre pressure regulation system. They can be driven with a significantly lower tyre pressure at the same load capacity. For the use of an RDA, this means: because the air pressure only has to be increased or decreased by a few bar, the necessary air pressure adjustment is lower. This saves a lot more time and increases the driver's willingness to use the system.

One more selling point to finish

Since 23 June 2021, after a break of around six months, farmers can again apply for a grant from the federal energy efficiency programme for the purchase of automatic tyre pressure control systems. The subsidy rate is 30 percent. Machinery pools and contractors are excluded. In contrast to the previously applicable rules, the eligibility conditions have been tightened. Only RDAs that cover all axles of the vehicle are now eligible; previously, retrofitting the rear axle was sufficient.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/f/csm_Werkstatttipp_Reifendruckregelanlage_8487f167b9.jpg)