The most important data of the currently used rim can be found stamped on almost all models on the market today. But after several years of operation or layers of lacquer, the information may no longer be legible. Then there is no way to avoid a rim measurement. Care is already required when reordering standard production rims. In many cases, the respective number of holes reveals the given connection dimension. But even in the segment of series rims, it can happen that the connection dimensions do not correspond to the standard and the hole patterns or the usual offset deviate. Workshops must take the following measures into account when measuring rims.

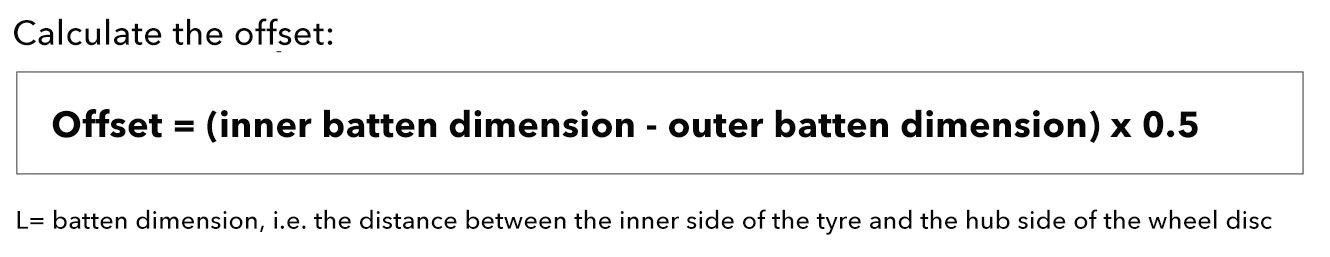

1. Offset

The offset indicates in millimetres how far the inner contact surface of the rim disc is offset outward or inward relative to the centre of the rim. An offset value of minus 50 means that the disc is offset 5 centimetres laterally inward towards the vehicle. This offset shifts the tread outward, making the track wider. A larger or positive offset value results in a smaller track width.

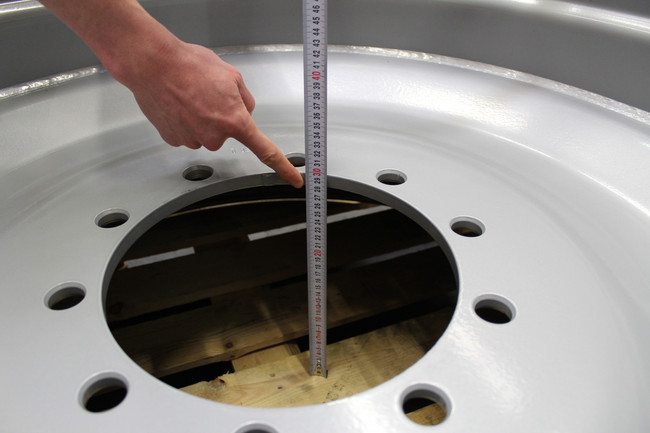

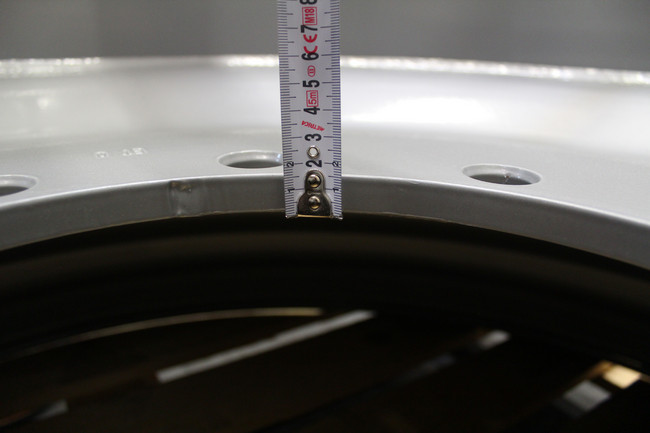

2. The batten dimension

One way to determine the offset is via the batten dimension (LM). A batten is placed over the outer and inner edge of the rim (or tyre) and the distance between the batten and the rim disc is determined vertically down towards the rim cup. In addition to the inner and outer distance between the batten and the base of the rim disc, you need the thickness of the rim disc. The offset is then calculated using the formula:

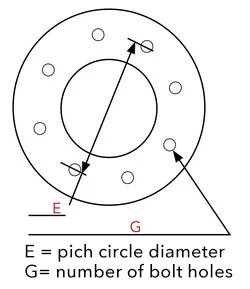

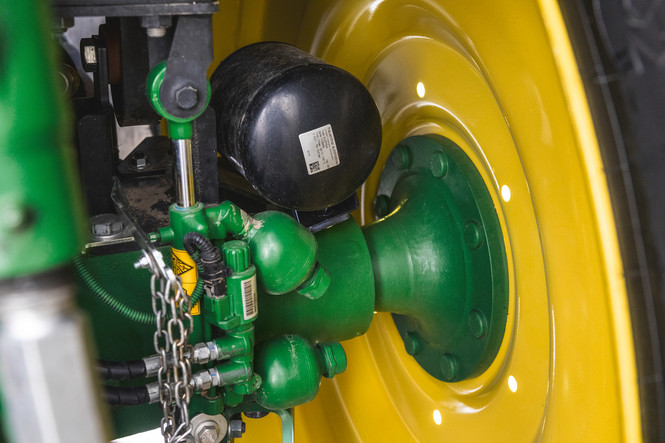

3. Pitch circle diameter

This dimension describes the diameter of an imaginary circle passing through the centre of the bolt holes. If there are an even number of bolt holes, there are usually two directly opposite one another, which makes it easier to determine the diameter by measuring the distance between the centres of the opposite holes. Odd numbers of holes require a different measurement. Take the diameter of the hub hole and add twice the distance from the hub hole edge to the bolt hole centre.

4. Number and design of bolt holes

Bolt holes can be cylindrical or countersunk, spherical or conical counter bores are common. In addition to this information - and of course the diameter of the bolt holes - it is important to know whether the countersink is on one side or on both sides of the rim cup.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/5/csm_Werkstatttipp_Felgen_richtig_messen_a9d1d4d1ac.jpg)