Row spacing of the crop

The most important question before using row crop tyres is:

“Which crops should the row crop tyres be used in"? Different crops require different row spacing. For example, maize cultivation (standard row spacing 75 cm), beet cultivation (45 cm row spacing) and fruit crops (with spacing of 50 cm) differ from each other. But what should be observed in all crops is the distance between the tyre and the plant.

Ideally, this should not be less than 10 cm, and this also applies to maize and beet in narrow sowing or other crops such as vegetable or medicinal plant cultivation. This means, for example, that with a row spacing of 50 cm (fruit crop) the tyre should not be wider than 25-30 cm, and correspondingly wider with a row spacing of 75 cm (maize).

The tyre fits to the machine

1. If the new tyre is different from the previous size, the height of the tyre is immensely important. The tyre must fit the machine. Not that it comes to unpleasant surprises and the tyres have no space under the mud guard, or there is no more ground clearance if the tyres are too small. Narrower tracks, on the other hand, can cause problems with the pressure vessel.

2. Now it remains to be clarified whether and which devices are to be attached. This is because the weight of the machine and the attachments must be suitable for the tyre. The tyre must have the right load capacity.

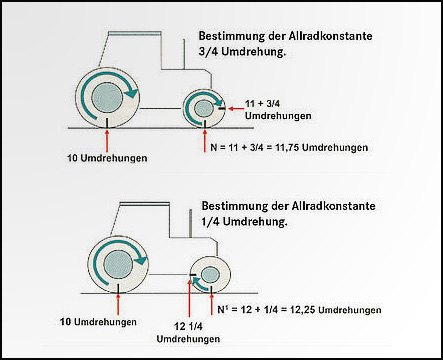

3. There is another important aspect to consider with all-wheel drive tractors: the transmission ratio between the front and rear axles must be correct in order to prevent possible damage to the transmission.

Order in time

Row crop wheels are usually custom-made. The production and glazing of the matching rim takes a few weeks. Prior to the tractor’s winter hibernation, think of the needs for the coming year and order. So it can start right away next spring without any delays!

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/5/csm_Werkstatttipp_optimae_pflege_639cafc81a.jpg)